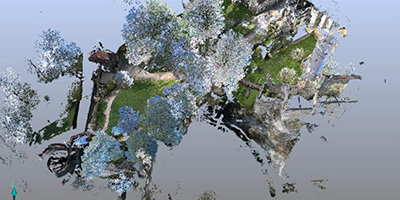

3D LASER SCANNER

The laser scanner is a precise measurement device that produces photorealistic three-dimensional images.

Its main features are the following:

- High Precision

- High Resolution

- High Speed

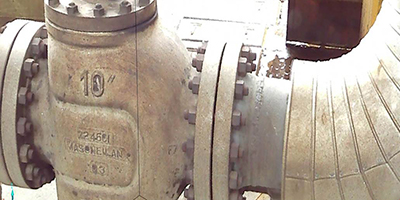

Measurement Quality

The large number of points measured by the scanner allows for a high-quality georeferenced image, even enabling the gathering of valve data.

Scan Views from Google Earth

If project position information is provided, the Google Earth View button will be available in the project preview. Pressing this button will open a Google Earth window of the project location in your default web browser.

Measurements

When performing Basic Engineering projects, Unit Revamping, Extensions, etc., the question often arises whether there is enough space in the plant for the inclusion of new infrastructure.

Since you can only rely on the CAD model to a certain extent, you will probably have to examine and take measurements of critical locations on-site. Using scanned reality, you can easily answer questions on your computer such as:

What is the height of the trellis? What is the distance between these supports? What is the height of this pipe? What is the diameter of a particular pipe?

Visualization Software

Delivery of visualization software to the client allows them to view all scanner projects.

The different available views are:

- Quick View

- Flat View

- 3D View

Advantages

With the Visualization Software, SCENE LT, you have the finished project on your PC desktop, providing several new advantages:

- Saving man-hours and transportation to the physical location for tasks that previously required a site visit.

- Visualizing structures.

- Verifying the type and diameter of pipes.

- Capturing valve data, etc.

- Checking levels.

- Verifying the condition of the different scanned equipment, accessories, floors, walls, and ceilings.

Independence

With the Visualization Software, you can make decisions independently, without the need for contractor companies.